Company

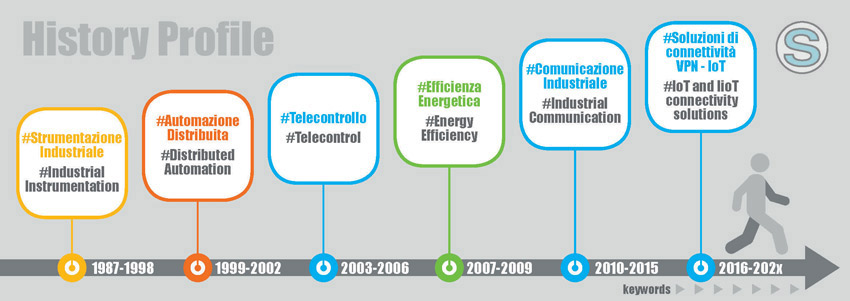

History Profile

New I/O modules with Profinet IO communication added to the range. These models provide configuration via CODESYS softPLC software and Siemens TiA Portal/ Simatic / Step7 design environment.

SENECA expands the range of industrial communication solutions with IIoT gateways and compact IEC 61131 PLCs. R-PASS devices provide digitized and interconnected industrial solutions.

SENECA offers a smart energy meter with universal input, dual Ethernet connectivity, current measurement inputs for CT and outputs for current/voltage, TV and Rogowski sensors.

The first 7" IIoT HMI is released, which includes gateway functionality, datalogger, alarm management, Wi-Fi router, logic, VPN technology and remote assistance / remote control functions also in the Cloud.

SENECA launches the R Series with a digital mixed I/O module and dual Ethernet ports. This series, including network analyzers, gateways and routers, is designed for flexible cabling needs and reduced installation space.

SENECA further expands the wide range of solutions for industrial communication with multi-function IoT gateways, remote alarm units and AC/DC transducers with ModBUS output.

SENECA is launching its Cloud-IoT solutions with microscadas and latest generation devices designed for Smart Factories.

SENECA introduces LET'S, a new VPN - IoT connectivity platform. The product range includes IEC61131 controllers, process controllers, industrial router / gateway, VPN server and dedicated software.

SENECA introduces a new range of industrial gateway/routers which defines a new SENECA standard for industrial communication

SENECA expands the range with new energy power meters and Single-phase or three-phase energy counters also MID certified. Test4 replaces its predecessor (Test3) with new features.

New hi-tech headquarters in Via Austria,26 Padua 5,000 sq.m.

MyALARM2 and Z-GPRS2 get their space in the market as datalogging and alarm-management devices.

SENECA introduces MY-0 like the first of the MyALARM family (nowadays MyALARM2). A GSM device with simple setup and high reliability designed for universal applications.

SENECA introduces electrical measurements and renewable energy products with high reliability and precision. Patented technology

CANopen I/O modules, expansion of S Series, Z Series and T Series with the temperature transmitter. Next generation modular LED indicators. New Headquarters in Via Svizzera. Business brand registration and patent tecnology in innovative inductive measuring. CoDeSys Alliance affiliation.

SENECA launches first OLED technology in the industrial market with Test3 (handheld calibrator) and the ModBUS S401 indicator. SENECA gets UL approval.

SENECA gets RINA approval and adapts the production to ROHS compliace.

This year we have the debut of K Line converters (only 6.2 mm width) and Z-RTU for remote telecontrol

SENECA joins the remote control field with standards and open technologies

We start the development of products and solutions for remote monitoring, Z-PC software platform and the first SMT testing and production line.

"Industrial Supplies" division was born while "Engineering Division" had been totally renovated.

SENECA Launches Z-PC line, ModBUS system for distributed automation and data acquisition

I/O ModBUS Z-PC system debuts on the market. New SENECA headquarters in Via Germania

SENECA obtains ISO 9001:2000 certification and launchs the first Z Series converters. SENECA becomes an italian leading manufacturer for panel instrumentation

Second-generation front panel devices with micro-processor

In this year SENECA srl has been founded. SENECA launches the first indicators and batch controllers for the process industry

Production of the first S Series, insulators, power supplies, backplane converters.

The production of the first precision instruments able to counteract the thermal drifts. In 1987 the S10 batch controller is one of the SENECA best-sellers. We have the production of the first LEDs without microprocessor

SENECA Sas was born with the aim of offering services to industry and innovative instrumentation for automation. We have the construction of the first automation and testing facilities.

EN

EN